This tiny foot print, combined with microwave, ultrasonic & centrifuge creates

a continuous stream of BioDiesel from Waste Vegetable

Oil.

PhytoTron500 is rated for 500 gallon per day and modular, so, upgrades are extremely inexpensive.

With Govt. Green Incentive rebate: Basic PhytoTron500 is under $5,000.00

Value added to The PhytoTron500 technologies of centrifuge, UltraSonic and MicroWaveSonoChemistry for under $9,000.00

that makes this little dynamo Accelerate the TransEsterification and Separations from taking days to taking only seconds.

These technological advances added to The PhytoTron500-That-Could are combined into this brand new, continuous flow processor called:

THE PHYTO-TRON 500

Click here for Technical data regarding UltraSonic SonoChemistry

Click here for Technical data regarding MicroWave SonoChemistry.

Click here for Video presentation of UltraSonic SonoChemistry-Chinese/English

PhytoTron500 is rated for 500 gallon per day and modular, so, upgrades are extremely inexpensive.

With Govt. Green Incentive rebate: Basic PhytoTron500 is under $5,000.00

Value added to The PhytoTron500 technologies of centrifuge, UltraSonic and MicroWaveSonoChemistry for under $9,000.00

that makes this little dynamo Accelerate the TransEsterification and Separations from taking days to taking only seconds.

These technological advances added to The PhytoTron500-That-Could are combined into this brand new, continuous flow processor called:

THE PHYTO-TRON 500

Click here for Technical data regarding UltraSonic SonoChemistry

Click here for Technical data regarding MicroWave SonoChemistry.

Click here for Video presentation of UltraSonic SonoChemistry-Chinese/English

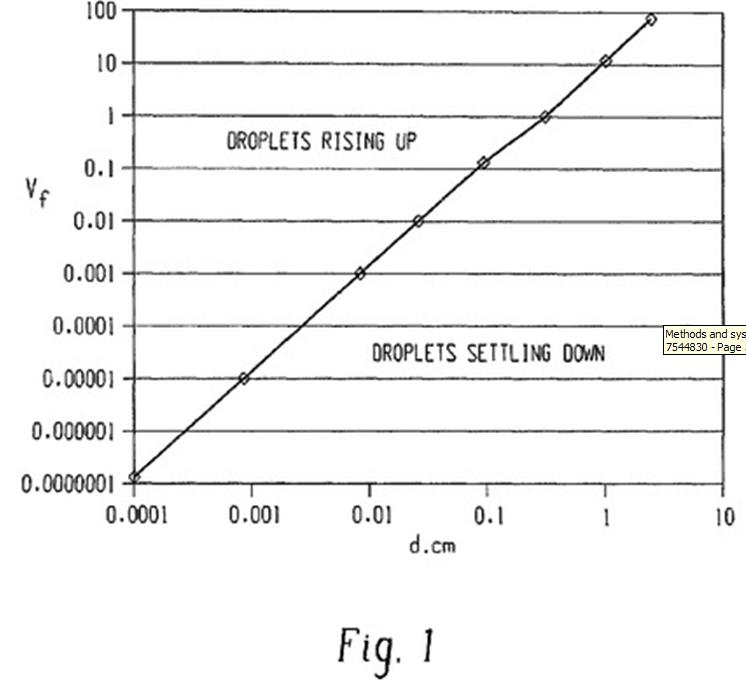

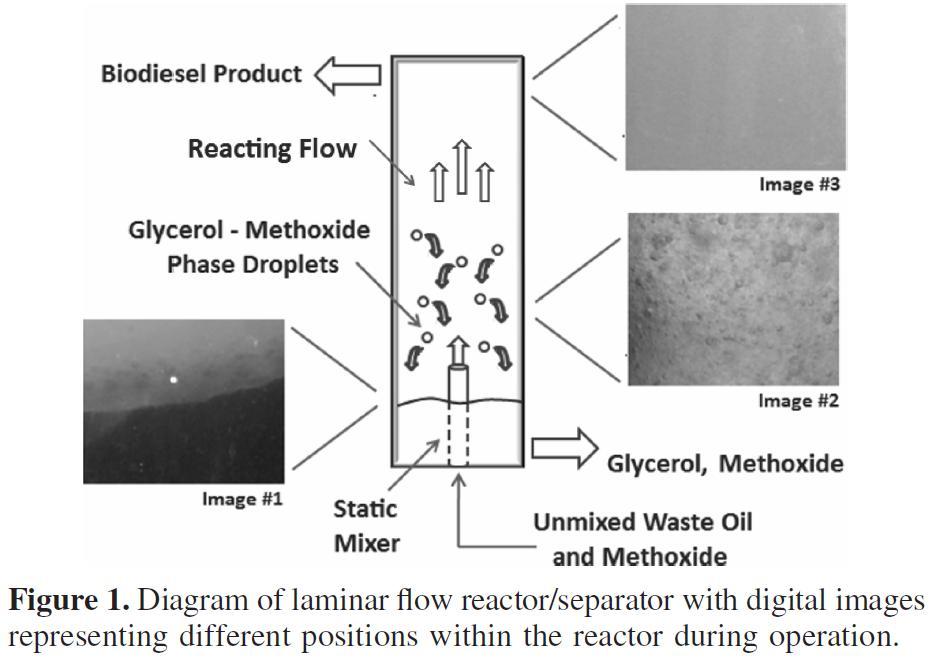

The basic principle of the PhytoTron500 is Exacting Flow |Rates'

causing separation in a continuous, drop by drop method,

with BioDiesel rising to the top, drop by drop, at precisely

the instant Methoxide & Glycerol are separated and fall,

drop by drop, to the bottom.

causing separation in a continuous, drop by drop method,

with BioDiesel rising to the top, drop by drop, at precisely

the instant Methoxide & Glycerol are separated and fall,

drop by drop, to the bottom.

Exacting Flow Rates of INPUT for Methanol, Sodium Hydroxide & Raw

Oil Feedstock.

Exacting Flow Rates of OUTPUT of separated BioDiesel at top and Methoxide + Glycerol at bottom.

Exacting Flow Rates CAUSE the separation to be CONTINUOUS at 1 liter per minute.

Exacting Flow Rates of OUTPUT of separated BioDiesel at top and Methoxide + Glycerol at bottom.

Exacting Flow Rates CAUSE the separation to be CONTINUOUS at 1 liter per minute.

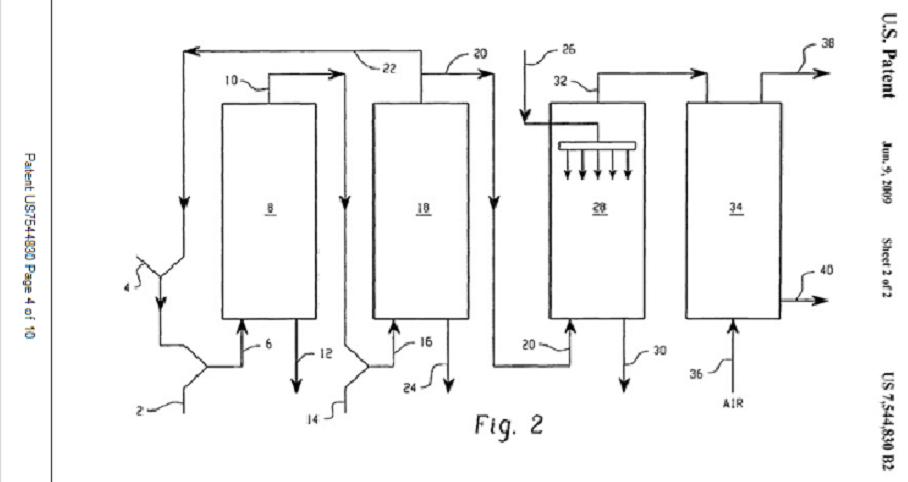

The PhytoTron design is based upon a patent-pending design from the University

of Connecticut.

The PhytoTron design VALUE ADDS both UltraSonic and MicroWave SonoChemistry.

The PhytoTron design VALUE ADDS both UltraSonic and MicroWave SonoChemistry.

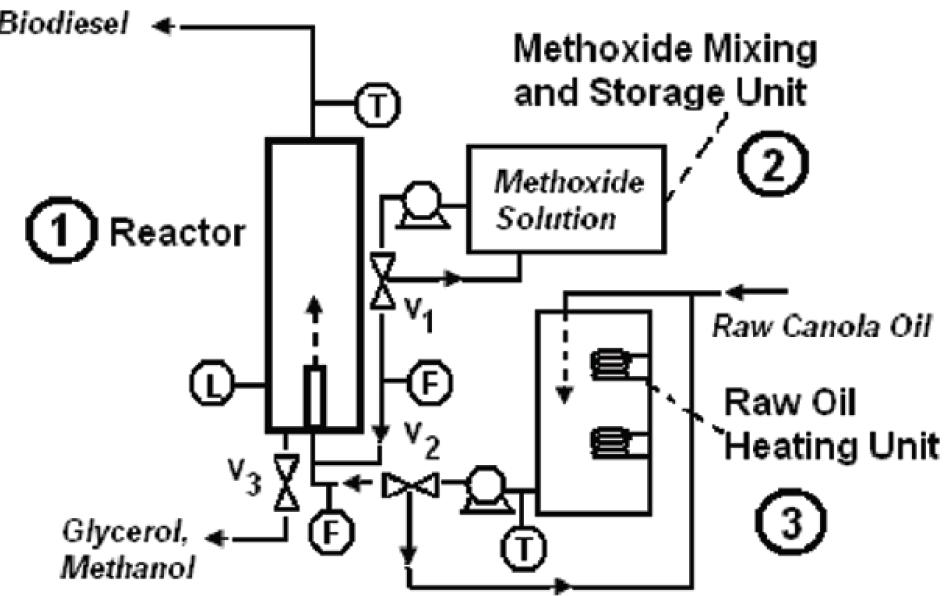

Schematic shows Exacting Flow Rates

of INPUT and OUTPUT necessary to CAUSE

free-flowing-continuous-processing of raw feed-stock to 99.9 percent conversion to BioDiesel.

free-flowing-continuous-processing of raw feed-stock to 99.9 percent conversion to BioDiesel.

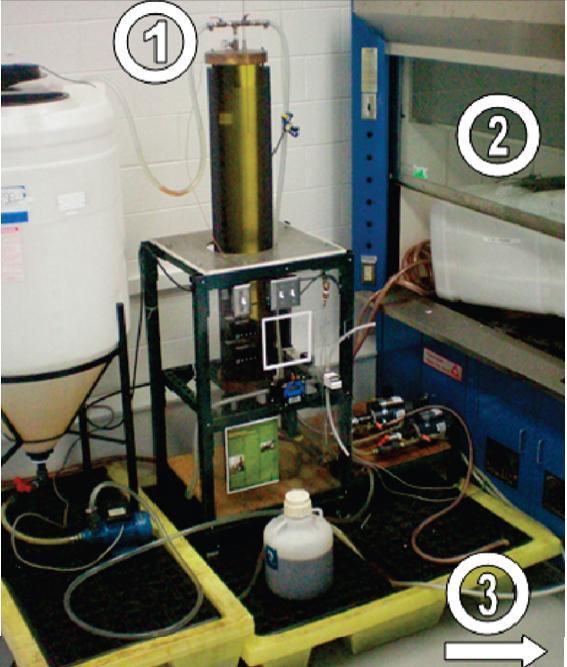

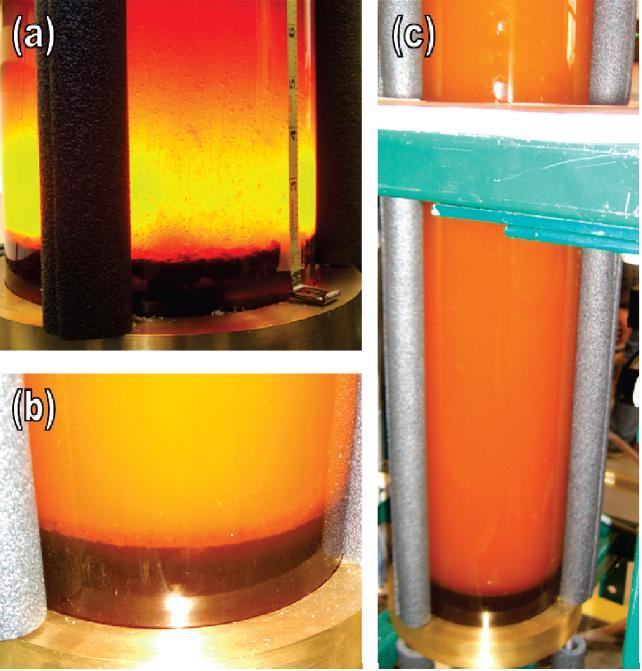

Photos show how Exacting Flow Rates of INPUT and OUTPUT will CAUSE

separation with NO high-pressure, NO high-temperatures and NO expensive equipment.

separation with NO high-pressure, NO high-temperatures and NO expensive equipment.

UConn Biodiesel Consortium

A consortium of faculty from several colleges recently formed the UConn Biodiesel consortium. A small scale production facility has been constructed to convert all UConn waste vegetable oil produced by Dining Services to biodiesel fuel for use in the UConn bus fleet. This effort includes many undergraduate students from the Chemical Engineering and Chemistry Departments, as well as a smaller number of students from Economics and Natural Resources. Byproducts from the biodiesel production process, such as glycerol and partially converted glycerides, are being evaluated as feedstocks for the polymerization of biodegradable materials.

A consortium of faculty from several colleges recently formed the UConn Biodiesel consortium. A small scale production facility has been constructed to convert all UConn waste vegetable oil produced by Dining Services to biodiesel fuel for use in the UConn bus fleet. This effort includes many undergraduate students from the Chemical Engineering and Chemistry Departments, as well as a smaller number of students from Economics and Natural Resources. Byproducts from the biodiesel production process, such as glycerol and partially converted glycerides, are being evaluated as feedstocks for the polymerization of biodegradable materials.

Researchers at the University of Connecticut reported last week that the fiber

crop cannabis sativa, also known as industrial hemp, has several qualities

that make it an attractive feedstock for producing biodiesel, a sustainable

diesel fuel made from renewable plant resources.

Industrial hemp can grow in infertile soils and does not require lots of water, fertilizer, or high-grade inputs to flourish, said researchers led by Dr. Richard Parnas, a professor of chemical, materials, and biomolecular engineering. It produces strong fibers that, until the advent of synthetic fibers in the 1950s, made it the premier product used in making rope and clothing around the world.

Currently, much biodiesel feedstock comes from crops that could otherwise be used for human food consumption, such as soybeans, peanuts, olives, and rapeseed. Similar problems face the production of ethanol, which diverts corn that could have been used for cattle feed (and ultimately consumed as meat by humans) into the fuel production market.

" For sustainable fuels, often it comes down to a question of food versus fuel," said Parnas. "It's equally important to make fuel from plants that are not food, but also won't need the high-quality land."

Parnas pointed out that much of the world still relies on hemp as a primary fiber, mainly because of its ability to "grow like a weed." But in fiber production, hemp seeds are often discarded, and, the researcher said, this waste product could be put to good use by using it as a fuel.

" If someone is already growing hemp," he said, "they might be able to produce enough fuel to power their whole farm with the oil from the seeds they produce."

Parnas and his team used virgin hemp seed oil to create biodiesel using a process called transesterification and achieved a high conversion efficiency with 97% of the hemp oil being converted to biodiesel. The university holds a patent on a biodiesel reactor system that could be customized to make biodiesel from a range of feedstocks, including hemp.

" Our research data could make buying a reactor system with our technology more attractive," says Parnas. "If we have data for the production of many different feedstocks, we can tailor the system to meet the company's needs."

Industrial hemp is grown in Canada, China, and European countries, among other places. But the DEA has barred its production in the US, leading to a bizarre situation in which American farmers have to sit idly by while industrial hemp products are imported from other countries. A number of states have passed legislation authorizing hemp research or production, but they are blocked by the DEA, which refuses to recognize any difference between high-fiber, low-THC hemp and low-fiber, high-THC marijuana.

Industrial hemp can grow in infertile soils and does not require lots of water, fertilizer, or high-grade inputs to flourish, said researchers led by Dr. Richard Parnas, a professor of chemical, materials, and biomolecular engineering. It produces strong fibers that, until the advent of synthetic fibers in the 1950s, made it the premier product used in making rope and clothing around the world.

Currently, much biodiesel feedstock comes from crops that could otherwise be used for human food consumption, such as soybeans, peanuts, olives, and rapeseed. Similar problems face the production of ethanol, which diverts corn that could have been used for cattle feed (and ultimately consumed as meat by humans) into the fuel production market.

" For sustainable fuels, often it comes down to a question of food versus fuel," said Parnas. "It's equally important to make fuel from plants that are not food, but also won't need the high-quality land."

Parnas pointed out that much of the world still relies on hemp as a primary fiber, mainly because of its ability to "grow like a weed." But in fiber production, hemp seeds are often discarded, and, the researcher said, this waste product could be put to good use by using it as a fuel.

" If someone is already growing hemp," he said, "they might be able to produce enough fuel to power their whole farm with the oil from the seeds they produce."

Parnas and his team used virgin hemp seed oil to create biodiesel using a process called transesterification and achieved a high conversion efficiency with 97% of the hemp oil being converted to biodiesel. The university holds a patent on a biodiesel reactor system that could be customized to make biodiesel from a range of feedstocks, including hemp.

" Our research data could make buying a reactor system with our technology more attractive," says Parnas. "If we have data for the production of many different feedstocks, we can tailor the system to meet the company's needs."

Industrial hemp is grown in Canada, China, and European countries, among other places. But the DEA has barred its production in the US, leading to a bizarre situation in which American farmers have to sit idly by while industrial hemp products are imported from other countries. A number of states have passed legislation authorizing hemp research or production, but they are blocked by the DEA, which refuses to recognize any difference between high-fiber, low-THC hemp and low-fiber, high-THC marijuana.

Objective 1: Assessing, mapping, and quantifying biomass feedstocks suitable

for Connecticut: The overall objective of this sub-project is to create a comprehensive

inventory of biomass feedstocks, including energy crops well-adapted to local

conditions, and available industrial products from household, community, industrial,

or agricultural streams, available to support the Connecticut bio-energy

industry,

and to conduct thorough evaluation of the effects of biomass feedstock production

on energy supply, agriculture and rural development, and the environment. Objective

2: Genetic Improvement of Poplar Plants for Bioenergy Applications: The goal

of this subproject is to evaluate growth performance and biomass production

of transgenic poplar plans and determination of stem cell size and number,

lignin and cellulose contents, fiber length, contents, and yields of transgenic

poplar. Vegetatively propagate selected transgenic poplar lines wil be used

for all proposed experiments. Two lines from each of the following groups:

weak expressers, medium expressers and strong expressers of GhDET2 gene, GhGA

20-oxidase gene or both genes will be selected. Fast growing poplar can be

an important bioenergy feedstock for the state of CT and the region. Objective

3: Improve Economic Competitiveness of Biodiesel: The goal of this sub-project

is to expand feedstock usage in biodiesel production to include low cost waste

materials and value engineer the production equipment to minimize required

capitol investment. Electricity production, fine chemicals and polymers may

all be produced from either the biodiesel product or the glycerol co-product.

Improved reactor designs will be sought for both the triglyceride transesterification

and free fatty acid esterification reactors. Heat integration of the production

equipment with compatible production systems will lower operating costs. More

cost effective technologies for converting glycerol to synthesis gas, direct

use of glycerol in fuel cells, and interactive electric power rate optimization

will be explored for electricity production. The derivatization of glycerol

for use as a blending agent with protein based plastics will be explored as

a means of enhancing the glycerol value. power generation (State of CT). Objective

4: Economic impact analysis and outreach: Integral to the research agenda is

inclusion of analyses of economic benefits adoption of these plants, production

technologies, and use of bio-energy would have on Connecticut and, possibly,

the northeast. Such analyses would, for example, seek to evaluate the benefits

of utilizing different feed stocks and conversion technologies, projecting

new employment and output from local bio-energy feedstock production and refining,

assessing the impact of new research dollars, and measuring the value of potential

improvements in health and the environment. The regular provision of up-to-date

assessments of the economic impacts of bio-energy will inform policy discussion,

will facilitate public understanding of bio-energy, and will encourage in-state

commercial development of feedstock production and commercial scale refining.